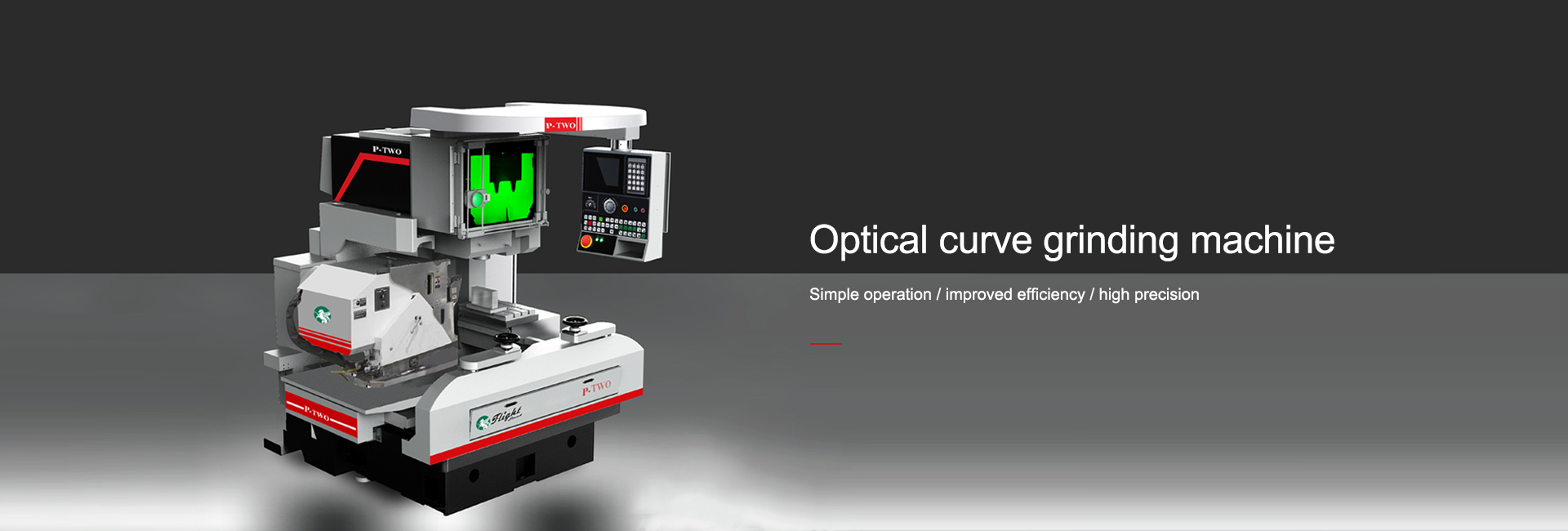

Grinding machines can process materials with high hardness, such as hardened steel, hard alloys, etc. It can also process brittle materials, such as glass and granite. Grinding machines can perform high-precision grinding with very low surface roughness, as well as high-efficiency grinding, such as heavy-duty grinding. The curve grinding machine is a type of processing machine tool, which consists of two parts: the main machine and the auxiliary machine station. The main machine is of a fully enclosed structure. On the right side of the machine body, there is a multi-functional worktable. On the left side, there is a grinding wheel frame and a slide seat. The upper part is a CCD detection device. The electrical cabinet is located at the rear of the main machine and is integrated with it. The auxiliary machine station is integrated with a dust collection device, a cooling device, an air balance and a brake control station. How to set too large technical parameters?

Technical parameters:

Item:

MD9040

Max. height of the surface grinding:

110 mm

Max.grinding length:

400 mm

Max. depth to be ground:

35 mm

X travel of the table:

400 mm

Y travel of the table:

100 mm

Turm range of work table C axis:

±30°

diameter of grinding wheel:

150 mm

grinding wheel speed:

3000~10000 rpm

Reciprocating travel of slider Z axis:

0~120 mm

Reciprocating times of slider Z axis:

20~250 min

X swivel range of the wheelhead:

-2°~+3°

Y swivel range of the wheelhead:

±8°

Travel of slider U direction:

60 mm

Travel of slider V direction:

80 mm

Grinding wheel motor:

800 W

Motor of Z axis:

1000 N

Motor of x,y,u,v,c axis:

1000 W

Axis number of conrol:

8 (Auxiliary Axis 2)

Min,input increment of CNC control:

0.0001 mm

Locus control mode:

Point position/line/contour cutting