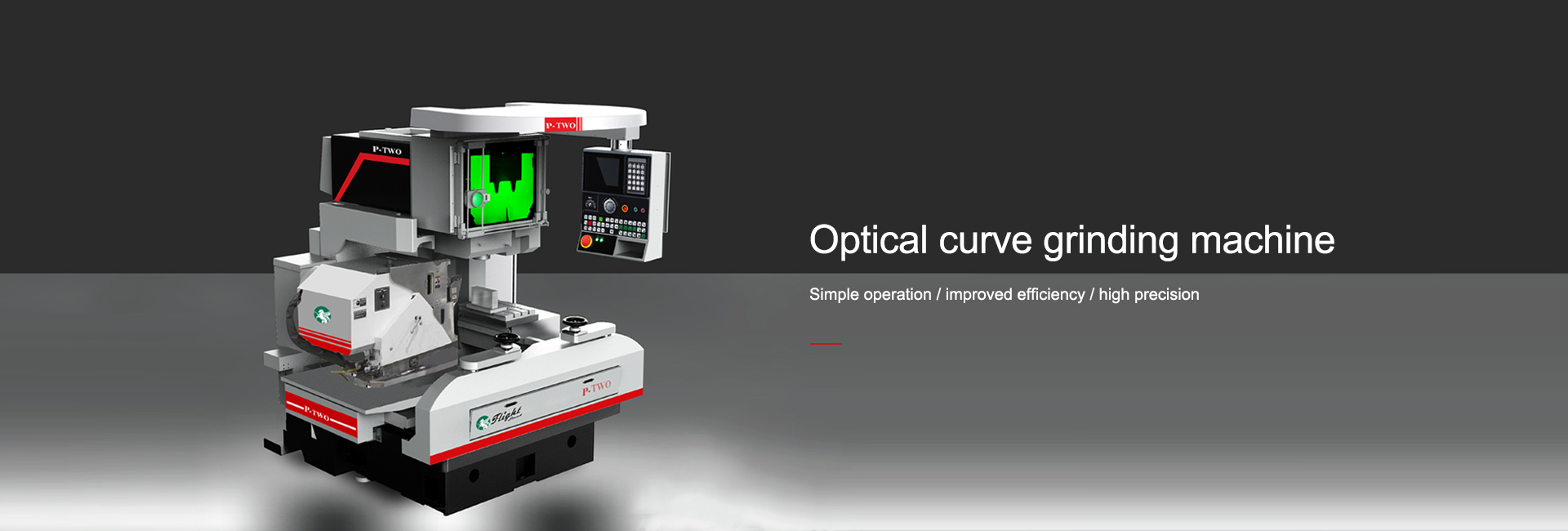

Optical curve grinding machines are used for grinding precise and complex surfaces, including straight lines, arcs and curves. During the grinding process, the workpiece and the grinding wheel can be magnified 50 times through the optical system and projected onto a screen. During operation, the operator can observe the grinding wheel's processing along the workpiece's profile at any time on the screen. The movement of the workpiece being processed can be operated manually or controlled by a DC motor to achieve the purpose of processing the profile.

Parameter:

The direct projection grinding size is 10X10mm, and the continuous section processing size of the worktable is 150X60mm.

The thickness of the processed workpiece is 50mm.

The main movement of the grinding head slide seat: a. The rotation Angle of the lower slide seat is ± 45 degrees; b. The longitudinal movement of the lower slide seat is 150mm; c. The rotation Angle of the upper slide seat is ± 45 degrees. d. Lateral movement of the upper slide seat by 100mm; e. The movement speed of the slide seat in the longitudinal and transverse directions is 0.2-1mm/min; 4-20mm/min

The rotation Angle of the grinding head around the horizontal axis is ± 10 degrees.

The rotation Angle of the grinding wheel shaft slide plate around the horizontal axis is ± 10 degrees and ± 30 degrees.

The travel of the grinding wheel shaft slide plate is 54mm.

The reciprocating stroke of the grinding wheel shaft slide plate is 54mm.

The reciprocating stroke of the grinding wheel shaft slide plate is 45-85 times per minute.

Workbench movement: a. Vertical movement of 100mm; B. Move horizontally by 60mm; C. Move 150mm longitudinally;

The diameter of the grinding wheel is 125mm;

The spindle speed is 3500r/min;

The working area of the projection screen board is 500X500mm.