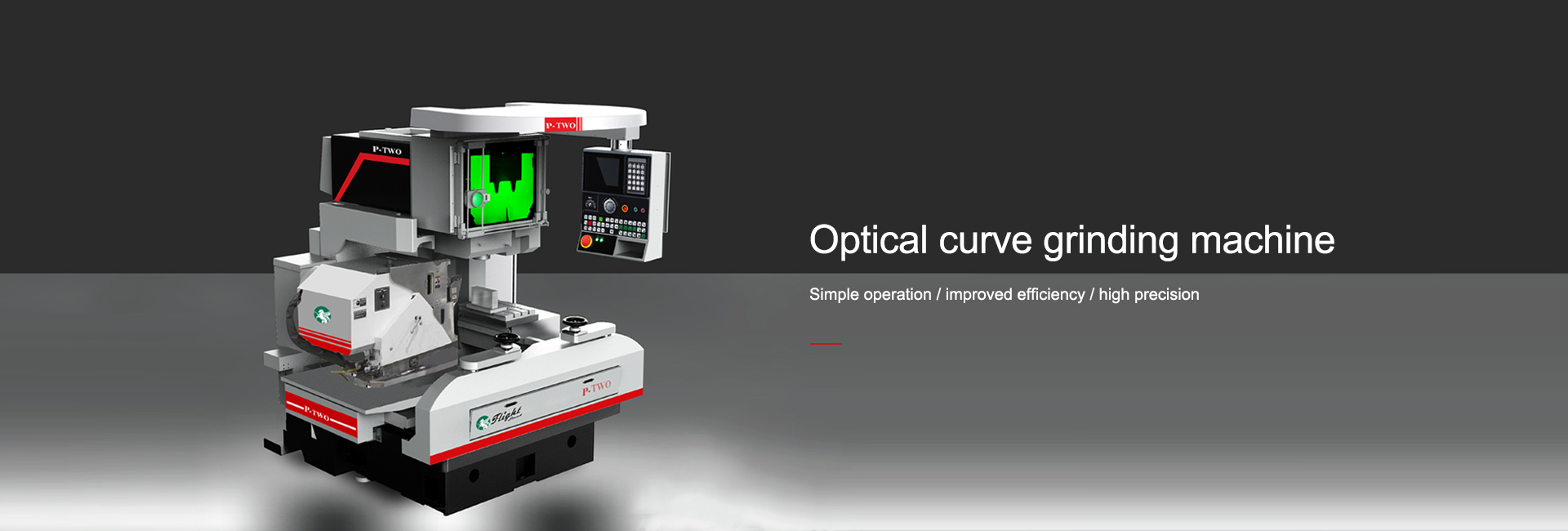

The curve grinding machine is a type of processing machine tool, which consists of two parts: the main machine and the auxiliary machine station. The main machine is of a fully enclosed structure. On the right side of the machine body, there is a multi-functional worktable. On the left side, there is a grinding wheel frame and a slide seat. The upper part is a CCD detection device. The electrical cabinet is located at the rear of the main machine and is integrated with it. The auxiliary machine station is integrated with a dust collection device, a cooling device, an air balance and a brake control station.

Overview:

The utility model is a multifunctional precision grinding machine tool that applies image recognition technology and integrates online detection of the machine tool, online compensation, online dressing of the grinding wheel and open multi-axis digital control. Integrating multi-axis digital control with image recognition processing, up to eight axes can be controlled, including seven servo rotary motors and one servo linear motor. Up to six-axis linkage can be achieved, and different combinations of control axes can be made. The utility model has the characteristics of elegant and generous appearance and strong human-machine compatibility, and is suitable for the processing of various precision and complex contour parts.

Processing range:

I. Production of Continuous Punch Die Base (Material: Steel, Aluminum)

Ii. Preparation of materials for continuous die molds

Iii. Manufacturing of various guide pins, guide sleeves, and various mold parts

Iv. Grinding of heat treatment templates

V. Forming and Grinding

Vi. Design and development of continuous hardware molds

Vii. Wire cutting processing of hardware molds and plastic molds

Viii. Electrical discharge machining (EDM), electrical discharge machining of tungsten steel, electrical discharge machining of general steel alloy materials, electrical discharge machining of threads (teeth), electrode manufacturing and processing

Ix. Optical projection grinding, tungsten steel forming grinding, super-hard alloy forming grinding, ceramic mold forming grinding, mold parts manufacturing and processing

X. Metal stamping die processing (special-shaped punches, lower die insertion, blanking and block insertion, bending punches, pre-breaking punches), manufacturing and processing of wire frame die parts

Xi. Processing of Plastic mold parts inserts.