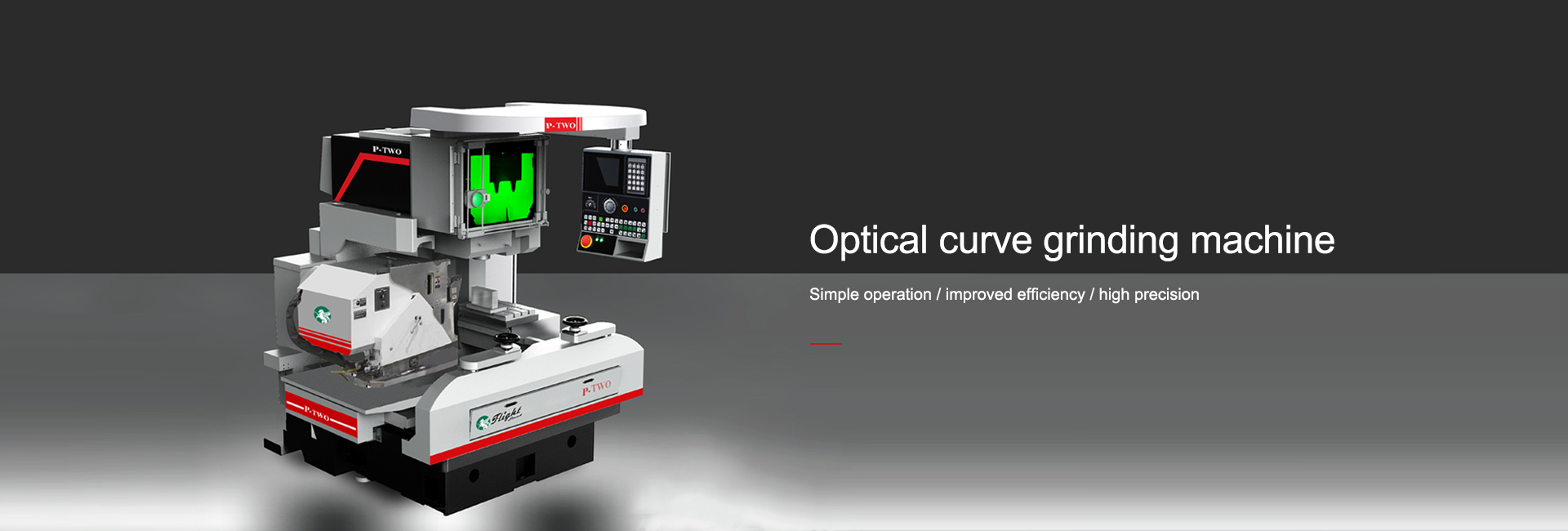

Optical curve grinding machine is a kind of machine tool with excellent performance for grinding curved surfaces, and it plays a significant role in mold processing.

(1) Working principle and structure

On an optical curve grinding machine, form grinding is carried out by using an optical projection magnification system to magnify the image of the workpiece onto a screen and compare it with the magnified image of the workpiece clamped on the screen. During processing, the grinding wheel is operated to grind the workpiece, removing the parts that cross the line until the contours of the image are completely aligned. It is mainly composed of the bed, coordinate worktable, grinding wheel frame and screen. The workpiece to be ground is fixed on the coordinate worktable by using special clamping plates, precision flat-mouth pliers, etc. The worktable can move longitudinally, laterally and vertically. The grinding wheel performs the main rotational motion, while simultaneously making linear reciprocating motion on the vertical guide rail of the grinding wheel frame. The grinding wheel frame can perform longitudinal and transverse feed motions, as well as swing angles along the vertical axis and the horizontal axis.

(2) The working process of the optical curve grinding machine

Before the form grinding of the optical curve grinding machine, according to the size and precision of the workpiece to be ground, a film magnification drawing is made on the drawing at a magnification of 20 or 50 times. During grinding, the magnified image is installed on the screen, and the optical projection magnification system of the grinding machine is used to project the shadow images of the processed parts and the grinding wheel onto the screen. Then, operate the grinding head to move longitudinally and laterally, allowing the cutting edge of the grinding wheel to grind along the shape of the workpiece until the contour of the workpiece image completely coincides with the lines in the enlarged image. Only then can the grinding process be considered complete. When performing form grinding on an optical curve grinding machine, due to the limitation of the screen size, workpieces of 20MM*25MM can generally only be ground. When the workpiece size exceeds this limit, segmented grinding must be adopted. Therefore, the enlarged drawing should be drawn in sections according to certain reference lines, and during form grinding, they should be connected with each other according to the reference lines.

(3) Precautions during grinding

When installing the workpiece, the processing part should protrude from the edge of the worktable and should first be adjusted to the focal plane of the objective lens.

Before starting up, an enlarged view should be drawn based on the selected division surface and projection magnification.